One system = countless possibilities

for diverse liquids and microdispensing applications

Experience a world of endless possibilities with just one system

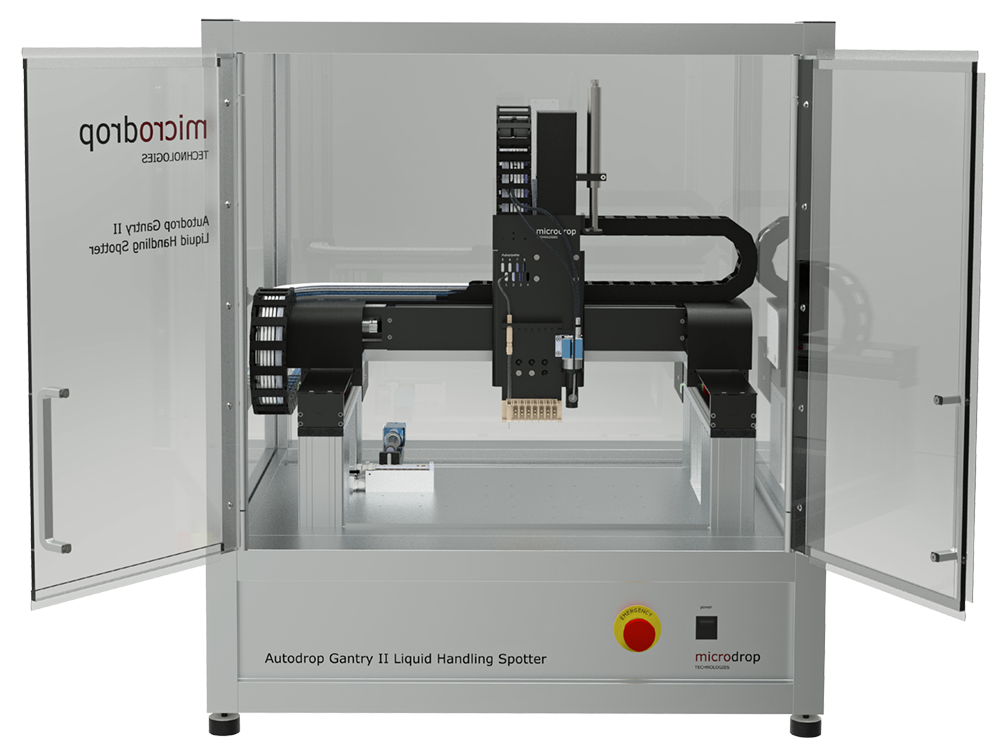

- Autodrop Gantry II Liquid Handling Spotter -

A modular and innovative instrument that is set to revolutionize the field of microdispensing.

This flexible device for up to 8 pipettes opens new doors for automated ultra-low liquid handling and high-precision non-contact dispensing, empowering you to achieve exceptional results with ease.

With the ability to control each pipette individually, you'll enjoy unparalleled flexibility and convenience. Leave behind the confines of traditional techniques and welcome the dawn of microdispensing's future with the Autodrop Gantry II Liquid Handling Spotter as your reliable partner.

Contact us.

We are pleased to help.

Customizable Extensions

There is much more than the modular concept. The integrated pipette washing station ensures precision, accuracy, and efficiency by preventing cross-contamination, reducing impurities, saving time and resources, extending the lifespan of pipette tips, improving result quality, and complying with quality standards.

For our system we also offer optional items that further enhance its capabilities and precisely match your application whether it is

3D Bioprinting , Microarray Printing or others.

For impeccable results, you need a controlled, turbulence-free environment that offers unparalleled cleanliness, a solution to neutralize electrostatic charges, or simply a vacuum table with heating and/or cooling capabilities.

No worries, we have a number of additional components on offer.

If this does not fit in the way you were thinking about, just let us know. Customization according to your specific requirements is also nothing out of the ordinary for us. Our goal is to achieve the best result for your application.

Let us take your experiments to the next level.

Ready for a game-changer?

Contact us

Let's discuss how the Autodrop Gantry II Liquid Handling Spotter can revolutionize your lab.

Unlock a world of possibilities with the Autodrop Gantry II Liquid Handling Spotter.

Discover the future of microdispensing with the Autodrop Gantry II Liquid Handling Spotter, your ultimate instrument for automated ultra-low liquid handling and high-precision dispensing.

Designed specifically to meet the needs of advanced non-contact microdispensing applications, the Autodrop Gantry II Liquid Handling Spotter empowers you to effortlessly achieve exceptional results.

Versatile Applications for Every Scientific Endeavor

Whether you're working with:

- DNA,

- proteins,

- cells,

- conducting multiplex ELISA assays,

- lateral flow applications,

- cell transfection arrays,

- diagnostic biochips,

- lab-on-a-chip experiments,

- diagnostic biomarker,

- microbiology assays.

Our instrument delivers unmatched performance on a variety of substrates including:

- membranes,

- cellulose,

- MTP plates,

- microfluidics,

- biosensors,

- cartridges,

- wafers,

- electronics,

- glass slides,

- customer-specific substrates.

Our system is a highly adaptable all-in-one solution

capable of tackling a wide field of applications.

Compact yet powerful, the Autodrop Gantry II Liquid Handling Spotter is like a cube with an edge length of only 80 cm while offering a generous travel range of 300 mm x 300 mm in standard. With an impressive resolution of <0.1 µm and a speed of 100 mm/s, our instrument is the perfect solution for even the most demanding applications.

Operating the Autodrop Gantry II Liquid Handling Spotter is a breeze thanks to the included user-friendly Autodrop Software. Featuring a self-explanatory interface, the software allows experienced users and newcomers alike to effortlessly assemble their individual processes.

Elevate your precision, efficiency, and productivity to new heights. Explore the possibilities and achieve exceptional results with the Autodrop Gantry II Liquid Handling Spotter by your side.

Contact us. We are pleased to help.

The key component for high performance microdispensing: the Autodrop Pipette

The Autodrop Pipette, first invented and brought to perfection by microdrop Technologies, is the key component inside the Autodrop Gantry II Liquid Handling Spotter for reaching the highest performance in microdispensing. The pipette´s body is made of borosilicate glass which results in the highest compatibility with almost every material you need to dispense. So, it’s not a special challenge creating structures of hydrogel, DNA or other cell-based solutions.

With its extra-long formed nozzle, it allows dipping up to 9.5 mm. The arrangement of the pipettes is designed to allow deep immersion into well plates without any problems.

The transparent housing of this unique pipette ensures that you can observe the liquid level in the glass capillary at any time. No more uncertain estimations, no more wasting precious samples. With this pipette, you have full control.

Therefore, the Autodrop Pipette is perfectly suited for the use in bioprinting or other life science applications like microarrays.

Broad range of diameters with several advantages

With its standard nozzle diameter ranging from 30 µm up to 70 µm and the possibility of customized diameters the pipette covers a wide area of resolutions and delivers the perfect match for your application. The option of a shorter dosing channel results in less sheer stress for sensitive materials like cells. In addition, the short dosing channel can prevent clogging as a result of sedimentation or agglomeration.

Contactless piezo based dispensing with a distance of just a few mm

With it’s piezo based dispensing the Autodrop Pipette delivers contactless and contamination free dispensing. You can just place the pipette tip in a distance of few millimeters and start with the printing of the desired structure.

Optional Items

Fixed and precise positioning of glass slides with the special Holder for Glass Slides

Sound as simple as it is.

Integrating our holder into your existing workspace couldn't be easier. Thanks to the convenient holes in the work surface, you can mount the holder quickly and easily.

With our holder for glass slides you can keep up to 9 sildes in a row and on the total area up to 3x9 slides. Quick and easy to attach to get a secure and reliable position for the microdispensing tasks.

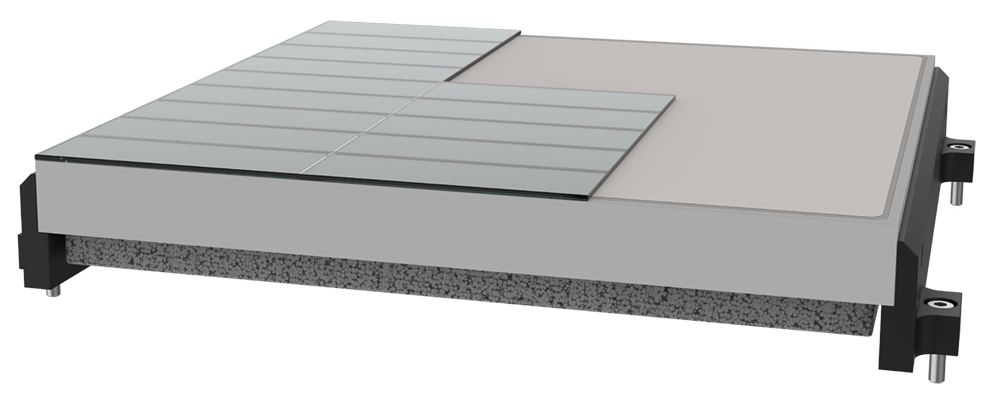

Perfectly fitting way of processing with the Vacuum positioning table with integrated heating and/or cooling options

Our vacuum table offers a range of options, including heating and/or cooling capabilities, to meet your specific needs.

With standard dimensions or customizable options, the vacuum table seamlessly integrates into the Autodrop Gantry II Liquid Handling Spotter, delivering exceptional performance and unmatched versatility.

Discover the numerous advantages that our vacuum table brings to your workflow. Here are just a few:

1. Precision and Stability: Our vacuum tables ensure unparalleled precision and stability during your work. With its robust construction and advanced vacuum technology, it securely holds your materials in place, preventing unwanted movement and minimizing errors.

2. Enhanced Safety: Our vacuum table provides a safe and reliable solution for securing delicate or irregularly shaped materials during machining, cutting, engraving, or other precision processes. Say goodbye to clamps and fixtures that can damage your workpieces or hinder your access.

3. Versatility: Whether you're working with small components, large sheets, or complex 3D objects, our vacuum table can be tailored to accommodate your specific needs. With customizable options, we can design a vacuum table that perfectly fits your workspace and requirements.

4. Heating and Cooling Capabilities: Take your work to the next level with the optional heating and/or cooling feature. This allows you to precisely control the temperature of your work surface, opening up a world of possibilities for thermally sensitive materials, temperature-dependent processes, or specific research requirements.

5. Efficient Workflow: The vacuum tables optimize your workflow by eliminating the need for time-consuming clamping or fixture adjustments. With its easy-to-use controls, you can quickly set up your workpiece, secure it with vacuum pressure, and start your precision work with confidence and efficiency.

6. Customizability: We understand that every laboratory or production environment is unique. That's why our vacuum tables can be customized to meet your specific requirements. Whether you need a particular size, shape, or additional features, our team will work closely with you to design a vacuum table that perfectly aligns with your needs.

Get into the turbulence-free journey with the Laminar Flow Module

Imagine a meticulously controlled environment where ambient air is expertly drawn in using advanced radial fans. This air is then propelled through a series of filters and flow straighteners, generating a remarkable laminar flow effect.

With laminar flow, air moves in perfectly parallel lines, creating a streamlined path free from turbulence. This exceptional air movement swiftly picks up particles present in the environment, efficiently transporting them away from your workspace.

Experience unrivaled cleanliness.

This laminar flow module will be integrated directed on top of our machine.

Prevention of contamination by ionized particles with the integration of the Ionization system

Tired of seeing your precious and precisely dispensed droplets being diverted by electrostatic charges? Look no further than our innovative ionization system!

Our ionization system is built directly into the Autodrop Gantry II Liquid Handling Spotter. By generating targeted ions, we neutralize electrostatic charges, eliminating the deflection of droplets. The ionization system provides you with the assurance of precise and reliable dosing.

It not only improves the accuracy of your dispensing but also minimizes the loss of valuable fluids. By eliminating electrostatic charges, you can optimize your resources and reduce costs.

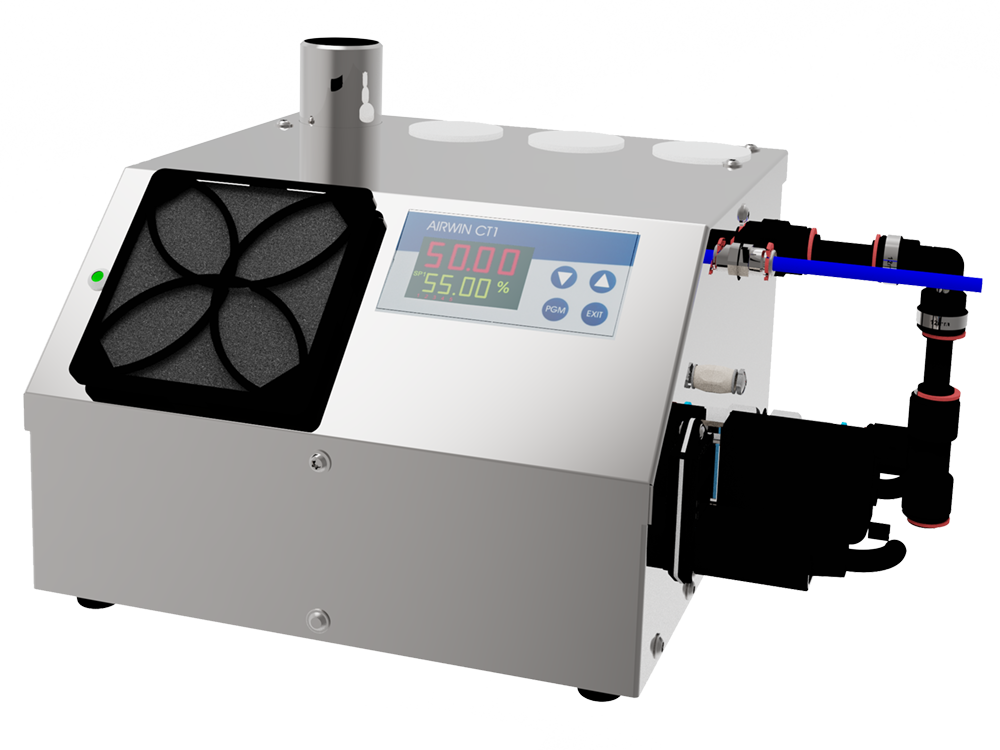

Create the perfect environmental conditions for your application with the integration of a Humidifier

Introducing the humidifier with integrated continuous controller - the ultimate solution for compact and precise humidification systems!

Experience the ease and efficiency of our universal humidifier, which comes equipped with an integrated continuous controller. With a simple connection of a humidity sensor directly to the humidifier, you can set up a highly accurate and compact humidification system in no time.

Our humidifier takes precision to the next level with its aerosol outlet pipes, enabling targeted guidance and distribution of the perfectly humidified air.

Say goodbye to uneven humidity levels and hello to a comfortable and controlled environment.

A Configuration for every budget

The Autodrop Gantry II Liquid Handling Spotter delivers unseen potentials and limitless possibilities. To give you an idea of these possibilities we show you three examples for possible configurations for different budgets. All systems will be delivered with a laptop to run your system straight away.

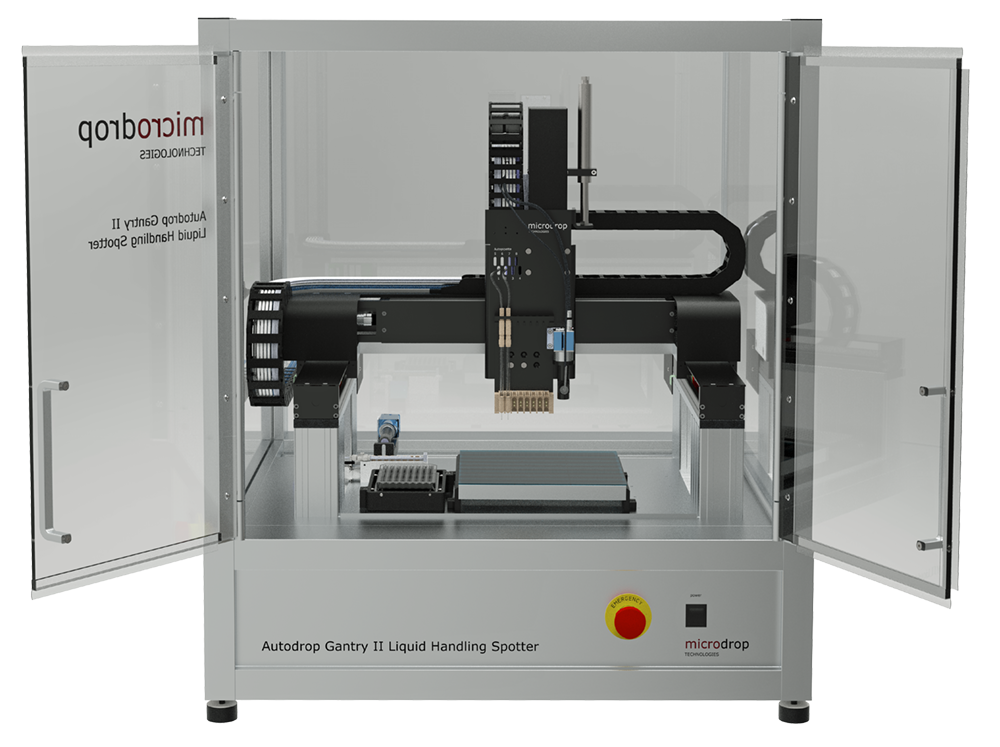

Basic configuration:

The basic configuration consists of the positioning unit itself equipped with one pipette at a time. To make sure there is a droplet the observation camera unit is mounted and for the filling or emptying of the pipette there is the precision holding unit for microtiter plates with 96 or 384 wells. A second camera is mounted parallel to the pipette so the dispensing result can be monitored after the dispensing process. The second camera can also be used to aim a target/fiducial on the substrate to dispense at a specific area. To enhance the cleaning process of the pipette the washing station is integrated. These are the basic components to run the system.

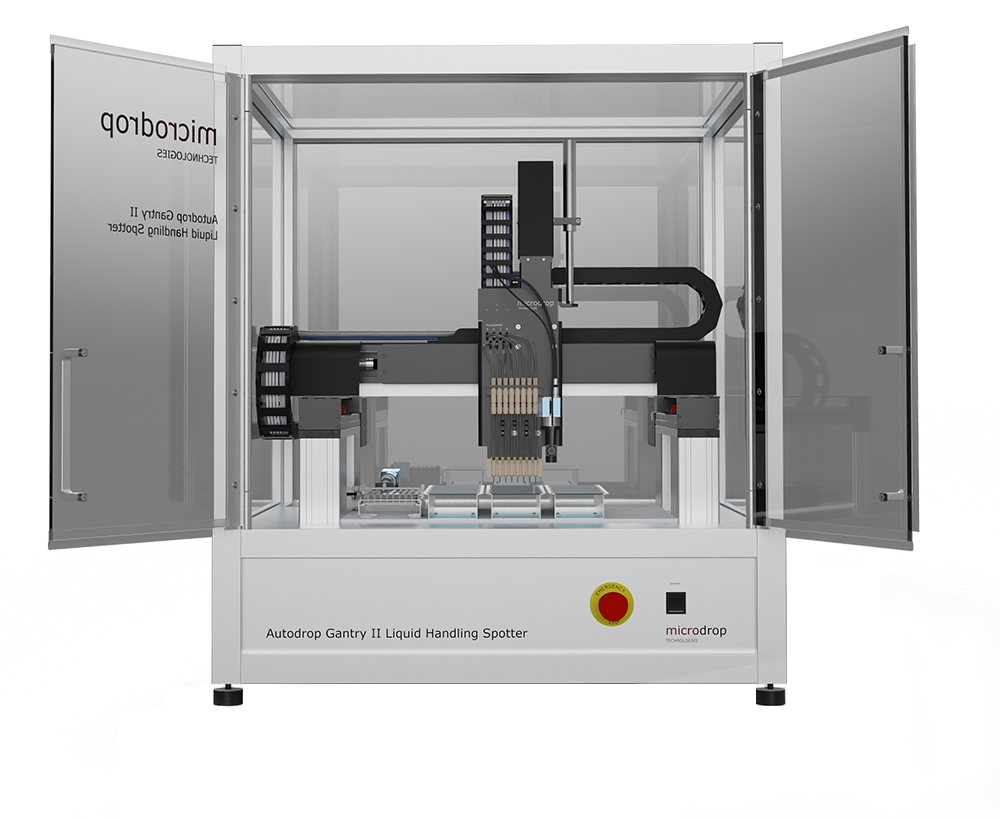

Advanced configuration:

The advanced configuration consists of the same components as the basic configuration. The advanced configuration uses two pipettes at the same time. A second holding unit for the substrate is integrated which delivers the basement for an enhancement in the dispensing precision. To prevent cells inside the droplet from dying the cooling option is integrated.

Pro configuration:

The pro configuration starts with the positioning unit and 8 simultaneously usable pipettes. In addition to the components mentioned for the basic and the advanced configuration the substrate holder can be cooled and or heated. To improve the dispensing process a unit for ionization and to create a laminar flow inside of the system are integrated.